Recycled Content (2)

To avoid the environmental consequences of extracting and processing virgin materials by using recycled and reclaimed materials.

- 50% of the volume of an 8-inch concrete masonry wall is GROUT

- Wider walls are greater than 50% grout

- CMU are appx. 2.5 sack mixes, whereas grout is appx. a 7 sack mix

- Greater amounts of SCM are possible in grout than in cmu

- Grout is hidden, no effect on aesthetics

| CalGreen | A5.405.4 (except structural frame) |

| CHPS | MW 3.1: 2 pts. |

| GGlobes | 5.4.1.1: up to 10 pts. |

| BDCv4 | MR BPDO - Sourcing of raw materials Op 2: up to 2 pts. |

| BDCv4.1 | MR BPDO - Sourcing of Raw Materials: up to 2 pts. |

| NDCv4 | GIB Recycled and reused infrastructure: 1 pt. |

| SITES | SD-MS 5.5 Use recycled content materials: 3-4 pts. |

| Applicable Products / Systems |

|

Concrete unit masonry includes low impact CarbonKind CMU by Angelus Block. Learn more here.

Concrete unit masonry includes low impact CarbonKind CMU by Angelus Block. Learn more here.

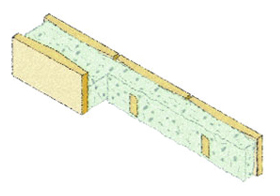

Masonry grout is approximately 50% or more of the volume of solid grouted concrete masonry, and has substantially greater potential sustainability benefit than recycled content in CMU alone. Fly ash, or fly ash combined with ground granulated blast furnace slag (GGBFS), may be used as a partial Portland cement replacement, and as a practical means of introducing significant recycled content into the masonry wall without adversely affecting aesthetic control of exposed masonry units.

The Concrete Masonry Association of California and Nevada recently conducted studies to demonstrate the effects of fly ash in masonry grout. Tests were conducted on mix designs with fly ash and fly ash/GGBFS as replacement of cement. Results indicated:

- Grouts with up to 30% by weight of Portland cement replaced with Class F fly ash can be treated as conventional masonry grout.

- Grouts with 40% to 50% by weight of Portland cement replaced with Class F fly ash are viable; compressive strength should be tested at 42 days, and should not have a significant effect on the overall project schedule.

- Grouts with 50% to 80% by weight of Portland cement replaced by fly ash (25%) and GGBFS (varying %) are also viable.

- These grouts have other benefits, such as increased workability.

Availability and specific mix designs will vary by local grout suppliers, who should be consulted for specifications. Please contact the Concrete Masonry Association of California and Nevada (CMACN), www.cmacn.org, or your Angelus Block representative for more information.

Recycled Content

Recycled Content