Recommendations and Guidelines

In 1992 the Concrete Masonry Association of California and Nevada (CMACN) and the Masonry Institute of America (MIA) held several meetings with masonry contractors, concrete block producers, water repellent treatment manufacturers, applicators, architects, and developers to discuss the proper design and construction methods to make concrete masonry buildings water resistant. Numerous recommendations and guidelines were developed including the following:

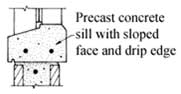

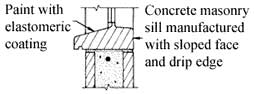

- Pay particular attention to the design phase of the project. Limit horizontal projections, sills, and tops of walls and waterproof those required by the project design with elastomeric coatings. Give special attention to the design of parapets.

- Cross reference the appropriate specifications sections in Division 4 on masonry construction (typically Section 04 22 00 Concrete Unit Masonry) with those in Division 7 on water repellent treatments (typically Section 07 19 00 Clear Water Repellents).

- Specify pre-installation meetings to familiarize all parties with the intended methods for prevention of water penetration. The masonry materials, construction, water repellent treatments, and treatment at joints should be discussed along with the expected results and testing procedures.

- Encourage the use of samples and mockups of masonry construction with the proposed water repellent treatments. Test the mock-ups for water repellency. Mock-up panels should be a minimum 5 ft. by 5 ft. panel and testing should be for at least two hours. Control joints and joint sealants should be included in the mock-up. Tests should be based on the Navy Hose Stream test or a similar field hose stream test.

- Ensure the use of full shoved head and bed joints (mortar for at least the thickness of the face shell of the masonry unit), if necessary through the use of third party inspections.

- Specify double struck joints for exterior masonry construction. Require beeholes visible from 5 to 10 feet to be filled by a qualified mason prior to application of the water repellent treatment.

- Fill cracks that exceed 0.02" in width or 5% of the joint length with mortar by a qualified mason or with joint sealer by a qualified applicator.

- Apply water repellent treatments in strict accordance with the manufacturer's installation instructions and recommendations, by a trained experienced applicator.

- Field test the concrete masonry walls after the water repellent treatment has cured to assure water repellency.

- Require a ten year material and labor warranty from the manufacturer and the applicator through the general contractor.

Efflorescence and Concrete Masonry Walls

Efflorescence and Concrete Masonry Walls